Solutions From Procurement To Completion

Construction Engineering Soil + Foundation

Geotechnical Engineering Investigation + Litigation Support

Forensic Engineering Arts + Entertainment

Live Performances

Museums + Art Displays

Pop-Ups

Signage

Studios + Sound Stages

TV + Film Production

Theaters

Theme Parks + Playplaces

Museums + Art Displays

Pop-Ups

Signage

Studios + Sound Stages

TV + Film Production

Theaters

Theme Parks + Playplaces

Ports + Coastal

Berths, Piers + Wharves

Bulkheads

Esplanades

Ferry Landings, Ship Terminals

Floating Structures

Ports + Terminals

Marinas + Breakwaters

Transfer Stations

Bulkheads

Esplanades

Ferry Landings, Ship Terminals

Floating Structures

Ports + Terminals

Marinas + Breakwaters

Transfer Stations

Public Infrastructure

Bikeways + Trails

Garage + Parking Facilities

Park + Recreational Spaces

Streetscapes

Utility Infrastructure

Water + Wastewater

Garage + Parking Facilities

Park + Recreational Spaces

Streetscapes

Utility Infrastructure

Water + Wastewater

Transportation

Airports

Bridges

Ports + Terminals

Rail Transportation

Roads + Highways

Ropeway + Linear Infrastructure

Bridges

Ports + Terminals

Rail Transportation

Roads + Highways

Ropeway + Linear Infrastructure

A leading full-service engineering firm renowned for our trusted, high quality, and innovative approach to solving complex challenges.

Sort News By

Mercy University Reveals Entrance Renovation

Mercy University’s Westchester Campus recently unveiled its redesigned main entrance,...

McLaren on CBS Mission Unstoppable Highlighting Women In STEM

A sneak peek behind the scenes filming special segments for the CBS show "Mission...

The Floating Wetland Habitat in Baltimore’s Inner Harbor Officially Opens

McLaren Engineering Group played a vital role in this transformative project, applying...

Engineering Feat: Giant Inflatable Dragon Perched on Empire State Building for House of the Dragon Season 2 Premier

Our entertainment engineers helped take HBO’s House of the Dragon Season 2 premier...

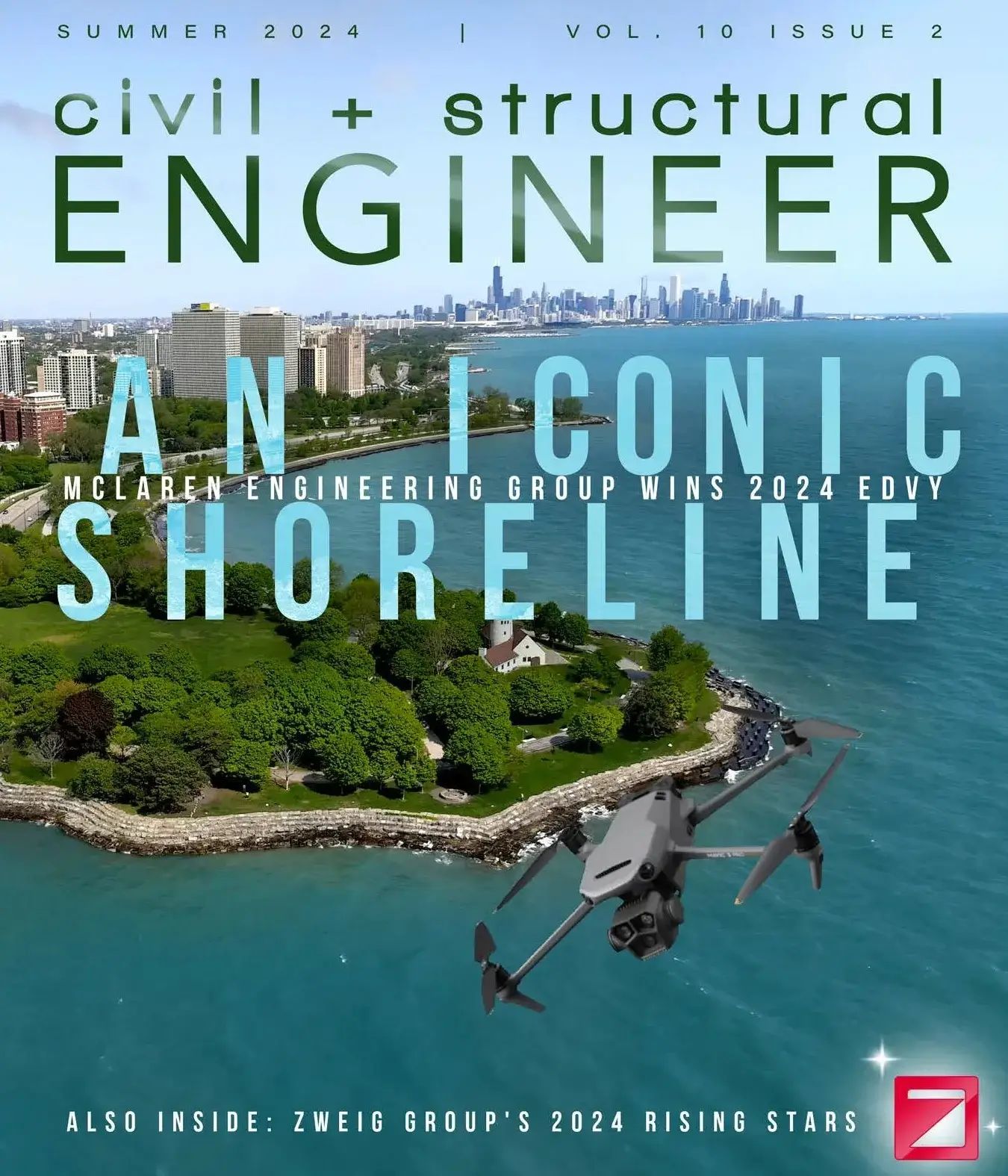

McLaren Wins the 2024 Engineering Drone Video of the Year Competition

After making it to the top five during the voting period, McLaren’s video was judged...